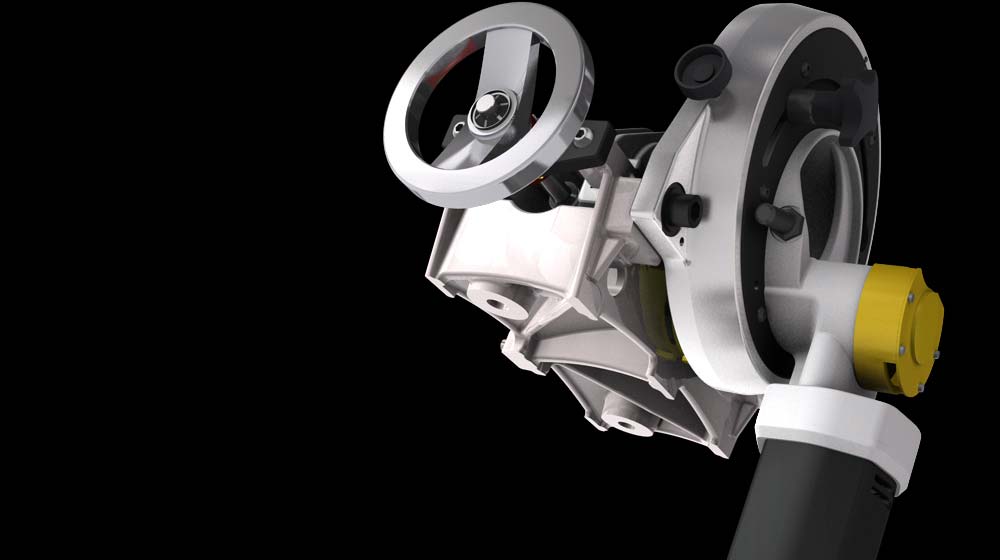

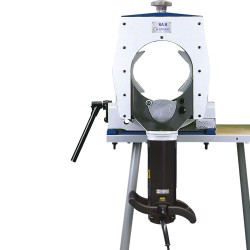

Orbitalum GF4 AVM - 1/2" - 4" Pipe Cutting & Bevelling Machine 115v

The GF series sets standards in orbital pipe processing! Numerous innovative functions combined with an ergonomic design give you significant advantages in the industrial prefabrication of piping systems.

Pipe Cutting and Bevelling Machine with automatic feed module AVM. This intelligent solution continuously controls the cutting speed depending on the torque and the parameter settings. The AVM improves the handling of the GF and RA machine and stops automatically after the cutting process. The restart inhibit does not allow an unintended start-up.

*DELIVERY OF THIS ITEM IS APPROXIMATELY 14 DAYS

• Right-angled, burr-free and cold machining process

• Deformation-free clamping system for thin- and thick-walled pipes

• Optimal preparation for the automated welding process

• Robust design with powerful drive

• Unique, automatically guided plunging process

• Multi-point clamping of the tube

• Fast adjustment of tube dimensions

• Cutting speed regulation

• Fast tool change

• Cut / Simultaneous Cut & Bevel / Bevel

Increased safety due to stationary tube

The proven process of "planetary cutting" is an important feature that is characteristic of ORBITALUM pipe saws. The saw blade dips into the cut and is guided orbital around the tube. The advantage of this is that a large pipe diameter can be cut with a small saw blade without heating the pipe.

Innovative clamping principle through multi-point clamping of the tube: The deformation-free clamping makes it possible, depending on the material, to cut.

The deformation-free clamping makes it possible to cut tubes with a wall thickness of 2 to 10 mm (0.079" - 0.394") easily and quickly, depending on the material. All high-alloy, non-alloy and low-alloy steels, aluminium, copper, brass, annealed cast iron pipe, general structural steel, black and galvanized steel pipe and plastic can be processed.

OTHER ADVANTAGES:

- AVM feed module for an automatic or mechanized cut-off cut, resulting in less physical strain for the operator.

- Optimized tool engagement at only one point of the tube at a time

- Optimized speed range (40-215 rpm), ideal for cutting high-performance materials (Hastelloy®, P91, etc.)

- Ergonomically optimized motor handle, thus safer operator position

- Cutting process in seconds

- Chamfering of tube ends parallel or separately to the cutting process

- Increased productivity

- Increased tool life

- More corrosion protection due to stainless steel jaw attachments (included)

- Cable incl. plug connection and quick release coupling for easy and convenient replacement of the flex swivel cable